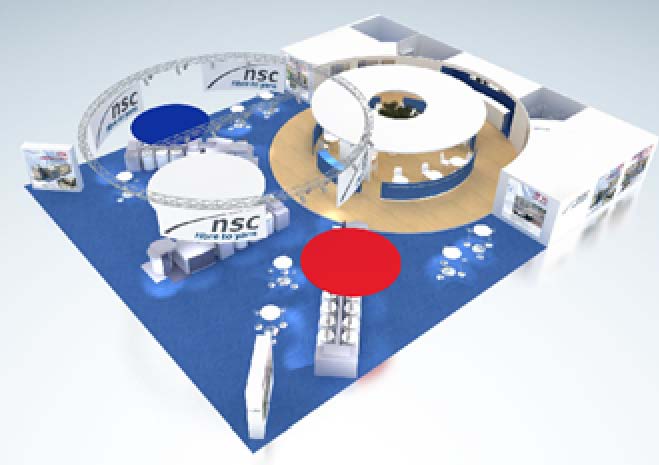

N. Schlumberger will participate at the ITMA 2015 which be held from November 12th to 19th, 2015 in Milan Italy in Hall 2 – Booth E-110.

N. Schlumberger developed a new GC40 chain gill exhibited on the booth, with a more universal head combined with a fully multi motor drive.

The GC 40 is the best off of the latest chain gill models created by N. Schlumberger

The GC 40 chain gill is user friendly, highly automated, saves money on energy and has low operational and maintenance costs and is therefore more cost effective.

N. Schlumberger exhibit also the GN8 a new intersecting based on the latest design of chain gill drive combined with universal drefting head of GN series.

The GN8 is design to process wool and any kind of wool like fibres.

It is particularly adapted to process delicate, fine and short fibres such as Cashemere, Silk or fibres with low cohesion.

Recently N. Schlumberger propose SEMI-WORSTED lines with a semi-worsted carding m/c model SW 35PP (2.5 m or 3.5 m wide), supplied by N. Schlumberger followed by preparation lines consisting of chain gills model GC 30 and finishers m/c model FMV41 / 42.

N. Schlumberger semi worsted card – one of the many top making machines offered by NSC fibre to yarn – from its innovative production range

- For all types of long staple chemical fibres

- 2.5 to 3.5m working width

- hopper feeder

- TRD drafting head

- Integrated suction

- Screen control

N. Schlumberger offers its customers an excellent after sales service. N. Schlumberger has very professional teams of experts for all technical issues. NSC provide quick assistance when needed, as well as training courses for customer staff’. The company also offers programs in audits for existing machines, kits for machine renewal and ongoing maintenance programs.

N. Schlumberger developed textile machinery with the latest technology for a variety of customer needs including small and big operations. NSC is well positioned to deliver customers fully integrated systems and deliver complete production lines from fibre opening and blending to finished bobbins. NSC works with other leading machinery manufacturers to supply specific equipment that is not in our product range but is complementary to it, and we manage installation from start to finish. We provide our customers guarantees and assurances’

All NSC fibre to yarn machinery is equipped with highly efficient motors (class IE2) for engines with 0.75 to 375kW. This is fully compliant with a new directive by EuP Technical Europe Lot 11 that supports the new IEC 60034-30 standard classification performance of electric motors.

Customers today appreciate that to stay competitive they need the latest textile machinery available. The machinery that is user friendly, highly automated, saves money on energy and has low operational and maintenance costs and is therefore more cost effective. To achieve savings NSC definitely see new machinery as a preferred option. NSC customers that have upgraded to the latest models experience a faster turn-around, better quality outcome and more trouble free production

We are looking forward to seeing you at the NSC stand!

We are looking forward to seeing you at the NSC stand!