The main topic is how to save costs when plastics are recycled.

The energy and operation costs have recently become decisive factors when plastics are recycled. Machine manufacturers have been called upon to find new solutions in this field. Herbold Meckesheim GmbH have done their homework and at the FAKUMA, will be presenting their new developments that have been produced at Meckesheim near Heidelberg, focusing on this aspect.

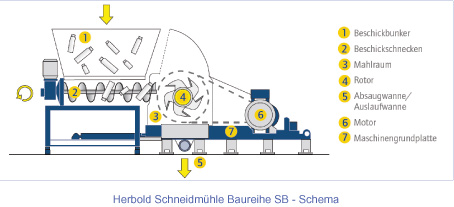

The new Generation: Herbold Granulators with Forced Feeding

The newly developed SB series granulators continue their way to the top. Herbold’s SB series are ideal for all types of size reduction applications from PET bottles to pre-shredded materials where maximum performance and cost efficiencies are a must. Here are two examples proving the capacity of these granulators: As a secondary granulator in continuous operation for barrels and hollow bodies, an SML 60/100 SB (rotor 600 x 1000 mm, drive 75 kW), can obtain a throughput of 3.400 kg/hr (screen size 8 mm).

- higher throughputs (30 to 50% higher capacity with the same granulator size compared to traditional granulators

- lower energy consumption (30 to 50% less power input compared to standard granulators)

- even rotor loads (fewer fines and less dust in the reground)

- automatic treatment of larger product quantities

Herbold Meckesheim has obtained the following patents worldwide for the screw feeding of granulators:

– US Patent Number: 7,793,872 B2

– EU Patent Number: EP 1 979 099 81

– Chinese Patent Number: CN 101374604 B

Developments from Herbold Meckesheim are ground-breaking. The wet grinding technique for granulators and many other recycling techniques that are the latest state of the art have been developed by Herbold.

Herbold Meckesheim will be present at FAKUMA 2015 (13.10. – 17.10.2015)

Hall A6 Booth 6502